Japan's Aquaculture Technology

CONTENTS

Kinki University Fisheries Laboratory’s Attempt to Solve a Food Issue of the 21st Century

The Kinki University Fisheries Laboratory is both a pioneer and leader in the field of aquaculture. The research into aquaculture methods undertaken by the laboratory over the past 43 years has prompted a great turnaround in the fishing industry from a “catching fish” industry to a “raising fish” one. The laboratory’s challenge was to make marine resources sustainable by use of “full-cycle” aquaculture and bring about a food revolution by cultivating the “fields of the deep blue sea”.

“The Fields of the Sea” – an Idea Born of One Man’s Belief and Passion

The idea of averting food shortages with Japan’s first fish farming industry could be said to be inspired by the fact that Japan is surrounded by sea, although another possible factor is the Japanese people, who demand marine resources as part of their food culture. Japanese are said to have eaten kuromaguro (bluefin tuna) since the Jomon period (circa 10,000 BC to circa 400 BC), and as the taste is so delicious, it is still highly popular even today.

However, due to a period of overfishing and the recent boom in the popularity of tuna worldwide, now there are fears that tuna resources will become exhausted, which has prompted considerable interest in how to manage this resource.

Separate to such predictions about the fate of tuna, Japan had already pressed ahead with a national-level project on aquaculture research. However, after the planned three year research period had elapsed, none of the research teams taking part had been able to raise natural juvenile fish for longer than a year. As the project had also ran out of budget, all the teams apart from Kinki University pulled out.

Why was only Kinki University able to continue the research and establish the techniques of modern aquaculture? Ph.D. Shigeru Miyashita, Head of Shirahama and Amami Experiment Stations told, "That is down to the strong beliefs and ideas of the university founder and first president, Koichi Seko."

Survive on “Self-reliant Research and Production Management”

Although Japan is a country blessed with marine resources, extensive falls in fish hauls after the war exacerbated Japan’s food shortages. Agriculture was also an essential industry for alleviating those shortages, but Koichi Seto had set his sights on the fishing industry. What he focused on was something that no-one had thought of before: “raising” fish rather than catching them.

Seto’s idea was as follows: “Think of the sea as one giant fish preserve. The sea is a field for us to cultivate” – and this way of thinking was the first step to establishing modern aquaculture techniques.

Japan’s fishing industry at the time was a “catching” industry centered on deep-sea fishing, and so Seto’s ideas were met with skepticism. Nevertheless, he aimed for a “cultivation” industry that would revitalize fishing and make marine resources self-sufficient.

Needless to say, Seto’s initial attempts were a string of failures. But fueled by his strong belief and passion, the aquaculture research continued. Although continuing this research posed financial problems, Seto adopted a similarly unique approach to overcome them. Usually, if research is being conducted by a university, the university bears the research expenses. Public institutions may also provide support depending on the circumstances. However, Seto adopted a financially independent and self-reliant managerial approach that could be called self-reliant “research and production management.” His mantra was: “If you want to research, earn the research expenses yourself.” In short, to produce things while researching, and research things while producing. This is known as an academic-industrial research production system in modern terms, but this practical science education was already being put into practice by Kinki University.

<Founding Principles of the Kinki University Fisheries Laboratory>

- Man-made juvenile fish for aquaculture use; do not take from natural resources

- Aquaculture: to raise parent fish and completely produce eggs and fry in the farm

- Aim for “full-cycle aquaculture” for all fish such as madai (Pacific sea bream) and hirame (flounder)

<Kinki University Fisheries Laboratory’s Attitude to Research>

- Manage the process from production to sale and do not rely on outside investment. This makes it easier for continuous research

Beating Food Shortages with “Practical Science Education”

Thanks to Seto’s passion and sense of mission, the laboratory started the world’s first cage-type fish preserve aquaculture in 1955, after which it succeeded in farming yellowtail. Subsequently, aquaculture of premium fish such as Pacific sea bream and greater amberjack also became possible, and attention was showered on the Fisheries Laboratory, which was opened in 1948 in Shirahama in Wakayama Prefecture.

Central to bringing about this success was Teruo Harada, the second president. The old method of aquaculture was to section off an arm of the sea to make an aquaculture pool into which the fish were released and reared. However, Harada used a cage-style fish preserve and reduced the size of the preserve to make it easier to manage. This was Hamada’s idea of “net-type aquaculture.” There are a number of advantages of raising fish in partitioned units: it is easier, it can support different fish species, it allows the units to be moved when the water quality deteriorates, and it can be carried out with little investment. This method provided the cornerstone to establishing modern aquaculture techniques and is the mainstream method of aquaculture worldwide even today. Using this approach, the laboratory succeeded in producing the world’s first flounder eggs and fry in 1965. The number of free-range hamachi (yellowtail) that had been developed using this aquaculture method suddenly grew from 2,570,000 in 1960 to 18,360,000 by 1964. The laboratory then built on its findings in full-cycle aquaculture by artificial hatching to produce results in support of hybrid technology, which can create superior fish breeds. Following that, in 1970, the laboratory cross-bred a yellowtail with a hiramasa (yellowtail amberjack), which has higher commercial value, to create the “burihira” (female yellowtail X male yellowtail amberjack) in an effort to selectively breed the yellowtail genus. Naturally, the laboratory successfully brought low-cost premium fish such as Pacific sea bream and yellowtail, which had been expensive up until then, to the market. This also led to a rapid growth in supply.

Advantages of net-type cage preserves

- Facilities can be set up and dismantled at little cost

- Easy to raise fish and run comparative tests by lot, size, annual production etc.

- Easy to manage fish (easy to handle shipping, selection, stock-taking etc.)

- Easy to observe fish

- Easy to move location (easy to remove fish from adverse environments)

Four great achievements in fish aquaculture at Kinki University

- Development of cage-type aquaculture (large production increases in fish farming)

- Development of full-cycle aquaculture techniques for 18 important fish varieties (development of techniques for artificially produced eggs and fry)

- Production and popularization of fast-breeding Pacific sea bream

- Establishment of full-cycle aquaculture techniques for bluefin tuna (source of bluefin tuna aquaculture techniques used worldwide)

Realizing the Dream of Full-cycle Aquaculture for Bluefin tuna

Bluefin are the largest of all the tuna. Large ones can grow to three meters in length and weigh up to 500kg. There are some distinct difficulties in the aquaculture of these giant beasts. Bluefin lay their eggs in deep sea areas, which makes harvesting eggs from wild adult fish close to impossible, while raising adult fish is also difficult because their giant size makes them hard to handle and requires a jumbo-scale rearing facility. Due to issues such as these, bluefin aquaculture had always been left untouched. That was until the problems were solved by Kinki University Fisheries Laboratory.

Catching wild juvenile fish and raising them would lead to overfishing of juveniles and result in depletion of natural resources as well as a reduction in the number of farmed fish. However, with full-cycle aquaculture – harvesting eggs from adult fish raised in a preserve, and then raising the juvenile fish artificially hatched from those eggs into adults, and then harvesting eggs from those adult fish and artificially hatching them to create a new generation – all of the processes in raising fish become possible to do artificially without relying on natural resources.

Kinki University first started researching full-cycle aquaculture of bluefin tuna in 1970, but it took another 32 years until the university finally succeeded in June 2002. It is said that reaching that goal was a process of trial and error that involved a string of hardships.

To begin with, the survival rate of bluefin tuna is very low. The mortality rate in the first month after hatching in particular is extremely high. We now know that three phases of high mortality follow one after another in the bluefin’s early life. The first phase occurs in the first 10 days after hatching (survival rate: 10%), a period of cannibalism occurs between 10 and 30 days that further reduces numbers (survival rate: 5 to 10%), and finally there is a clearly visible “collision” period three months after hatching when the young tuna crash into the walls of the preserve and die (survival rate: 0 to 0.1%). In total, it is said that only 0.03% of hatchings survive for a full year.

The laboratory first succeeded in harvesting eggs from raised adult fish in 1979, and also succeeded in raising the eggs into juvenile fish. However, by the 47th day after hatching, all of the juveniles were dead, with the largest measuring 57mm. In the years that followed, the juveniles continued to die within a few tens of days, until in 1983, the reared adults stopped laying eggs at all. No eggs were laid for the next 11 years, but the laboratory was in no mind to give up. The fish started laying eggs again in 1994, at which point the laboratory set up an in-house bluefin project team, recognizing that bluefin tuna were completely different from other types of fish, and set about developing techniques for eggs and fry production. As a result of the team’s scrupulous bluefin rearing observations, a number of important points came to light, such as the characteristics of various bluefin ecologies and developmental stages.

By acting on these points, the team was able to increase the survival rate year-on-year using measures such as enlarging the fish preserves, increasing the number of feeding occasions, developing an artificial feed mixture, and employing night-lighting technology and fluorescent lights at nighttime to stop the light-sensitive bluefin from dying by crashing into the tank walls. As a result, the survival rate one month after release had extensively increased to 49.6% (in the same 30m diameter-sized preserve as the reared adults). Around 400 fish made it to two years’ of age (weighing 5 to 15kg) and the team could achieve a certain level of production from a single fish preserve.

As a result, all the eggs and fry used for aquaculture nationwide are now full-cycle aquaculture eggs and fry. The survival rate from hatching to 90 days old was 0.03% in 1996, but has now risen to around 1%, while around 70,000 juvenile fish measuring approximately 30cm from nose to tail had been produced as of 2011.

Bluefin Tuna Branding Strategy

Kinki University has been shipping farmed bluefin tuna since it first started aquaculture testing, and the quality of this tuna is positively evaluated by the market as well. In 2005, Kinki University registered the tuna it farmed under the trademark “Kindai bluefin” and turned it into a brand. What’s more, the university started shipping to America and registered the “Kindai” brand as a trademark in America also in 2009.

Farmed fish produced by Kinki University are given a “diploma” featuring a QR code, which enables traceability of this food item. Subsequently, information is available about each fish’s aquaculture history (such as the feed and medicines given to it) and consumers can check the production history of the fish they are about to buy right there and then while they are shopping. Making such information publically available can also be expected to keep fish producers on their toes too, leading to the supply of safer, more reassuring farmed fish.

With safety in mind, Kinki University farms bluefin in an environment that causes them as little stress as possible and never puts antibiotics in their feed. The bodily mercury levels of Kinki bluefin are said to be half the level of those in the wild. Generally, it is thought that the larger the fish, the more mercury it contains, and so eating too much bluefin tuna could lead to excess mercury intake, which is especially dangerous for pregnant women. Even The New York Times has warned against it in a past article. Against a backdrop like that, building a “Kindai” bluefin brand – fish produced by full-cycle aquaculture – should be easy.

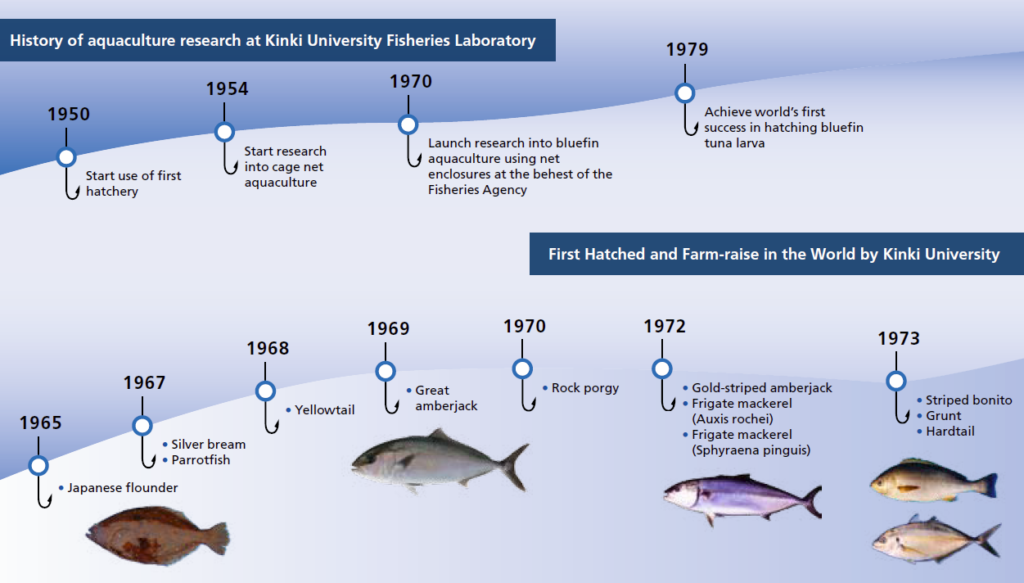

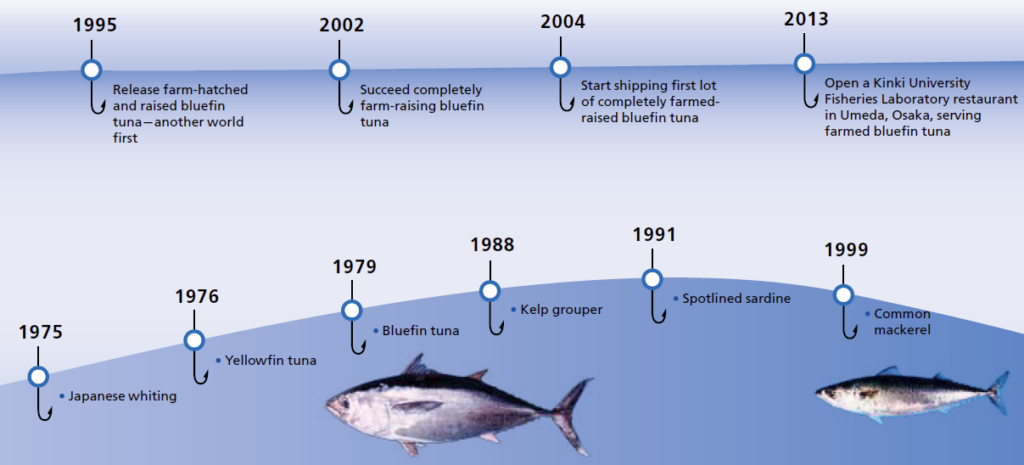

<History of aquaculture research at Kinki University Fisheries Laboratory>

1950 Start use of first fish rearing facility

1954 Start research into cage (net)-type aquaculture

1970 Start research into bluefin aquaculture at the behest of the Fisheries Agency

1979 Artificially hatch bluefin tuna – a world first – and succeed in raising juvenile fish

1995 Release artificially hatched bluefin tuna – another world first

2002 Successfully complete full-cycle aquaculture of bluefin tuna

2004 Start shipping bluefin tuna produced by full-cycle aquaculture

2013 Open a Kinki University Fisheries Laboratory restaurant in Umeda, Osaka, serving farmed bluefin tuna

<The 18 species of fish for which Kinki University Fisheries Laboratory was the first in the world to successfully produce eggs and fry from artificial hatching>

1965 Flounder * Since the laboratory became the first in the world to produce eggs and fry from artificially hatched flounder in 1965, production of eggs and fry for 18 species of fish has become possible. This has played a central role toward preventing the exhaustion of marine resources, and has made it possible to actually produce marine resources and bring them to market. The fishing industry has turned from a “catching fish” industry to a “raising fish” one.