Japan's Recycling Technology

CONTENTS

From Products to Products: Catch word is “Treasure Hunting”

By Ryoji Shimada, staff writer

“Those who contemplate the beauty of the earth find reserves of strength that will endure as long as life lasts. There is something infinitely healing in the repeated refrains of nature --- the assurance that dawn comes after night, and spring after winter.” This is a quote by Rachel Louise Carson, a renowned marine biologist and environmentalist, and author of the 1962 nonfiction bestseller, “Silent Spring.”

Nobody knows how many of us really think this way. But expectations have been growing toward companies in Japan to adopt policies toward conservation and the environment. According to the survey of 1,000 men and women from age 15 to 64 in the greater Tokyo area, undertaken this past February by Japan’s biggest advertising agency, Dentsu, 74.9% of respondents said they believe major companies should adopt environmental measures. And one way for companies to respond to growing public expectations might be through the adoption of “repeated refrains of nature” to the production process.

If They Are Separated, They Are Resources

A glimpse of “repeated refrains of production” can be viewed at the Panasonic Eco Technology Center, or PETEC for short. The facility is one of about 50 recycling plants in Japan which process four types of home appliances: TVs, washing machines, air conditioners and refrigerators.

More than a million discarded appliances were disassembled and processed here last year alone. Inside a stock area, used items are piled high, awaiting recycling. In the past, such products were demolished and then dumped in land fills. But now the law requires them to be recycled. They are not only demolished, but also reprocessed and sorted into reusable resources. Kazuyuki Tomita, president of PETEC, says, “We break up products back into separate materials. If the materials are mixed together, they are waste; but if they are separated, they are resources.”

From discarded products, PETEC mainly collects such materials as steel, copper, aluminum and plastics. Plastics used to be dumped, but now they can be separated into three varieties: polypropylene (PP), polystyrene (PS) and acrylonitrile butadiene styrene (ABS). Those materials are then sold and used to manufacture new products.

From 2001 until March this year, this plant demolished and reprocessed materials from more than nine million consumer appliances. Steel alone came to 136,179 tons, equivalent to the volume used in 166,072 passenger cars. Copper came to 21,247 tons, enough to reproduce 85 statues of the Great Buddha of Nara. And the 12,080 tons of aluminum were equivalent to the volume utilized in 105 jumbo jet aircraft.

The recycling ratio per unit is also high. On a net weight basis, 88% of discarded air conditioners were recycled in 2010. The figures for washing machines and refrigerators were 86% and 76% respectively. Cathode-ray tube TVs came to 85%. All of these exceed the current requirements set by law.

According to Japan’s Law for Recycling of Specified Kinds of Home Appliances, which stipulates the ratios required for recycling of each of the four items, more than 70% of air conditioners should be recycled back into materials in terms of their total volume; washing machines 65%; refrigerators 60%; and CRT TVs 55%. To be included in the statistics, the recycled resources should be at the level that enables them to be sold for reuse. Recycling plants make profits by selling recycled resources as well as by earning subsidies from recycling fees paid by end-users.

Concept Is “From Products to Products”

PETEC started its operation in the spring of 2001, coinciding with the enactment of the abovementioned law, which requires consumers to pay a fee for recycling at the time they discard those home appliances. The Ministry of Economy, Trade and Industry (METI) explains the purpose of the law: “We need to reduce waste and recycle valuable parts and materials and then construct a so-called ‘closed loop economy’ in which used materials can be made into new products.” PETEC’s basic idea is in accord, but phrased more simply: “From products to products.” President Tomita explains the rationale for the law. “Japan is short of natural resources. We rely heavily on raw materials from abroad. But we have resources from ‘existing products.’” Adding one more reason, which is that the available landfills are becoming filled up, he expresses the plant’s slogan: “Treasure Hunting.”

Accepting Study Tours

That slogan may sound catchy to kids and might be a great way to explain the facility to them in a simple manner. One of PETEC’s five aims is to accept study visits for environmental education. Groups composed mainly of elementary school and junior high school students visit the plant daily in a group. Annually the total number of plant visitors comes to around 12,000, which includes overseas visitors from 107 countries. To open up the facility and be geared for those study visits, show rooms provide explanatory panels and hands-on displays of the recycling process. Visitors can also see the actual process in action.

The four types of used appliances are processed in separate areas and each area can be observed from an elevated observation deck. Some of the reports written by elementary school children are pegged on the board. One read, “I was worried that Japan would be full of garbage. But now I am relieved and understand how important recycling is.” Another young visitor wrote, “I feel a sense of appreciation for those working hard to recycle disposed products.” Adult visitors also are surprised to see how meticulously the appliances are broken up, and understand it is worth paying the recycling fee. Overseas visitors are also surprised at the recycling process, but also perplexed to hear that consumers are obliged to pay the recycling fee. In some countries, it is a common practice to simply sell appliances as scrap. “But they are thrown away after some valuable parts are extracted, or their printed circuit boards are soaked in chemicals to retrieve metals,” laments Tomita.

Disassembling the appliances

Sorting out various home appliances made by different manufacturers

Visitors to the plant are requested to put on a headphone to be able to hear the guide’s voice over the noise. But while actually in that working area, a visitor can easily hear what the guide is saying. It is not so noisy as one might expects and the air is relatively clean and not unpleasantly smelly at all. This environmentally conscious policy accounts for another of the five aims: “co-existence with the local community.”

<The process of recycling refrigerators>

Analyzing the type of thermal insulation and chlorofluorocarbon.

removing a compressor

extracting chlorofluorocarbon

fragmenting into pieces

selection of plastics into PP, PS and ABS

selection of metals into steel, copper and aluminum

Co-existing with the Community

The plant is located in a scenic area surrounded by mountains and rice paddies, in an area famous for Yamadanishiki, a special type of rice used in the production of sake (rice wine). Typically recycling plants tend to have an unfavorable image, as people associate them with piles of obsolete products stacked outdoors under the sun. So at first, the local community adamantly opposed construction of the plant. “Everybody understands the need for recycling plants, but nobody wants one in their backyard,” says Tomita. He worked to change the negative image and wanted to prove that such a plant can be operated in this delicate bio-system. How was that accomplished? One way was to keep a low profile; openness to the public was another way. To suppress noise, they thickened walls and adopted newly invented low-noise cutter blades. To prevent spread of dust, they vacuum clean from the ceiling and the floor. To prevent contamination of the water table, they filter waste water and recycle it. To prevent eyesores, the trucks delivering discarded appliances to the plant are completely covered, rendering their cargo invisible. And to gain the community’s trust, the plant makes public data related to its waste discharge to the public regularly and holds a meeting with the locals twice a year. “Locals now admit to us that their misgivings were made-up,” says Tomita with a smile.

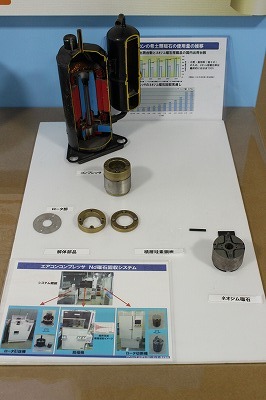

The other three objectives are of course recycling four home appliances designated by the law and giving feedback to new production development so that the next generation products can be more easily disassembled and recycled. Lastly, they uphold the development of new recycling technology. This is also in response to requests from the locals. Initially the area was supposed to be developed for high-tech industries and adjacent to the plant, RICOH operates a semiconductor factory and FUJITSU a cell-phone factory. As mentioned above, plastics are now separated into three kinds and separation work has become much faster through use of near-infrared light and fast air stream technologies. They also try to extract more valuable metals, like neodymium magnets, or try to utilize resources such as through converting the glass from CRT TVs’ tubes into glass wool, which can be used for refrigerators’ thermal insulation. CRT TVs’ glass used to be recycled back to new CRT TVs’ glass. But including in developing countries, the demand is falling, so other uses for the material needed to be developed.

PETEC aims to raise the recycling ratio by extracting other resources and recycling other consumer electronics. “Now it is very common to use recycled paper for photocopy paper,” says Tomita. “I want to create an image like this for products manufactured with recycled ingredients.” As of 2010, the rate of recycled resources incorporated into all Panasonic products was 13.6%. The company hopes to raise this to 16% by 2018.

Growing Awareness Is the Drive

But what are the benefits, exactly, for manufacturers using recycled resources? Are there advantages to using recycled resources? The answer, we were informed, seems reasonable enough. “We use recycled materials because we are afraid of exhaustion of resources,” asserts Machiko Miyai, Director of Corporate Environmental Affairs Division at Panasonic. She also raised the point that the costs for recycled resources don’t fluctuate to the degree as do natural resources. But more important, the reason is purely because it is “better for the environment.”

Recognition of society’s growing demand for major corporations to place greater emphasis on the environment has made the company realize that meeting such demands can also generate profits. Currently the company sells products incorporating recycled resources at the same prices as conventional products. Many surveys show that if prices are the same, consumers would prefer to buy environmentally conscious products. By 2018, the company has set a target that No.1 eco-conscious products will constitute 30% of total sales.

Environment Awareness Is Borderless

Public awareness toward the environment is not, of course, limited only to Japan. If anything, it might be even greater overseas. The Principles of Responsible Investment (PRI), which were launched by former UN Secretary General Kofi Annan in 2006, is an initiative and a set of aspirational and voluntary guidelines for investment entities wishing to address environmental, social, and corporate governance issues. As of 2011, over 900 investment organizations have ratified the principles and the number is still growing. Similarly, Socially Responsible Investing (SRI) has been practiced in the West for a long time and has been attracting a lot of attention in Japan as well.

But how about developing countries? Can they afford to consider the environment in their fast-paced economies? When viewing them in terms of their infrastructure, they are forced to consider the environment in any case. Miyai thinks that people in those countries tend to be more energy conscious than those in developed countries due to lack of electricity. There are places where water resources are scarce, or where electricity is limited. Miyai thinks it is important to manufacture products matched to the targeted market. Panasonic’s CUBE split air conditioner is such a product that targets the Indian market. Not only does it generate less noise and require less electric power, it also limits the functions, resulting in use of fewer resources as well as a lower price. It has scored a major hit.

This reduction of total resources utilized is part and parcel of Panasonic’s “resources recycling” policy in accordance with Green Plan 2018 --- Panasonic’s new environmental action plan to transform itself into the No. 1 Green Innovation Company in the Electronics Industry by 2018, the 100th anniversary of the company’s founding. The above-mentioned 16% target of total recycled resources used for production of new goods is one of the targets set to attain this goal. But Panasonic is already acclaimed as an environmentally friendly company both at home and abroad. It ranked first among 475 manufacturers in the Nikkei Environment Management Survey for three consecutive years, and was named to the Global 100 Most Sustainable Corporations in the World as well as numerous other listings. What makes the company so meticulous, and what’s the drive behind it? Since the company’s founding in 1918, it has maintained a firm management philosophy, one aspect of which is raised in its “Sustainability Report 2011,” which states: “We have the basic concept of the ‘company as a public entity of society.’ All the management resources of a company --- including the people, money, and commodities --- come from society. While the company engages in business activities using the resources entrusted by society, it also develops along with society, and so the company’s activities must be transparent, fair, and just.” Miyai also stresses the need for corporate social responsibility to be an environmentally friendly company. But at the same time, she notes it’s impossible to improve the earth’s environment by one company’s effort alone. “We want many more people to become aware of our efforts, and want to tackle environmental issues together,” she asserts.