Turning Agriculture into Industry— Rising Above Environmental Dependence

CONTENTS

Plant Factories – Their Potential for Improving Food Availability Within Agricultural Industrialization & Constraint of Resources

Developments involving the industrialization of agriculture are again showing new life.

New production systems called “factory production” or “plant factories” are becoming established as heightened consumer concerns about food safety and security add to the background of increased instability of harvest due to unseasonable weather and regulation of corporate style participation in agriculture as a business is relaxed.

Factory production for agricultural products refers to facilities that perform planned production of plants throughout the year by controlling through artificial means, the optimal environment for cultivation of plants. This means the monitoring and control of the amount and quality of light necessary for photosynthesis, water and nutrients, temperature, humidity and concentration of CO2 inside the facility. Also within the facility, land productivity and work efficiency is improved by continual multistaging of cultivation shelves and partially mechanizing the work processes involved from cultivation to harvest. For this reason, controlled environment for food production, in addition to having stability and consistency in four areas (yields, harvest timing, quality and price), has major collateral effects such as reduced use of fertilizer and water, enhanced safety of food products, more effective utilization of land, development of related industries and expanded employment opportunities. Combined further with the creation of specialized environments and genetic recombination technology, the production of newly functional plants may also become a possibility. As of April 2009, there were about 50 facilities in Japan that fell under the heading of plant factory. METI (the Ministry of Economy, Trade and Industry) together with MAFF (the Ministry of Agriculture, Forestry and Fisheries) is moving ahead with a plan to triple that to 150 locations within three years.

Challenges Here & Abroad In Food Supply

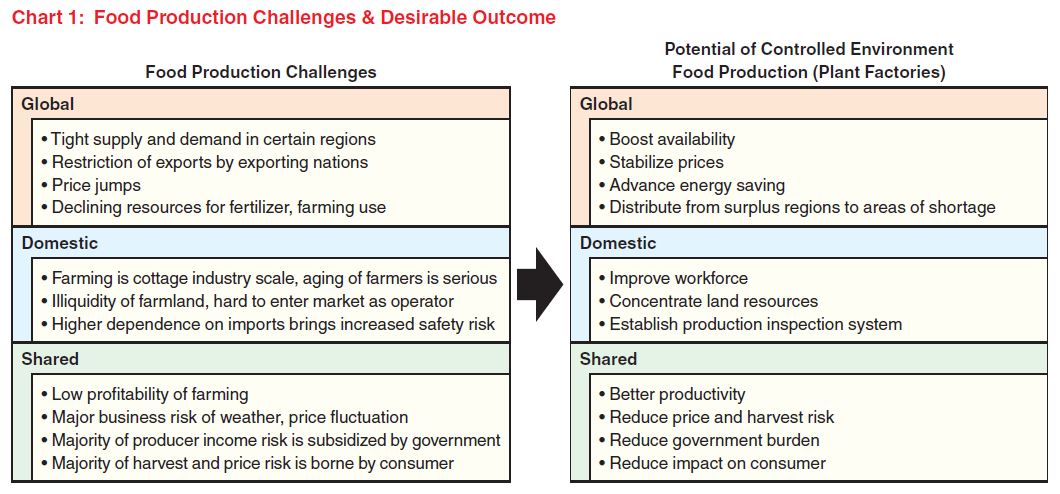

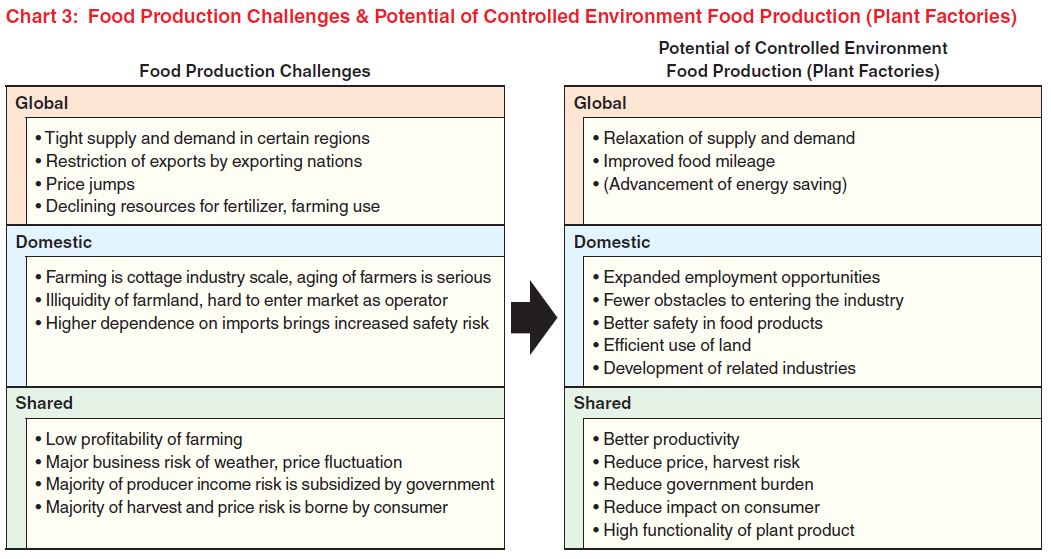

In terms of food supply there are various challenges to be faced both in Japan and overseas (see Chart 1). From around 2005 to 2008, when food prices including grain prices jumped exponentially on a global basis, some of the producing nations would use restrictions on exports to put the brakes on supply instability. In Japan, in addition to societal and structural problems including the scale of most farms being on the level of a cottage industry, and the problem of the aging of farm operators, our increased dependence on imports brings about heightened consumer worries about the safety of food products. From the very beginning major challenges of food production have been the operating risks of weather and disease, which have their origin in the form that agricultural production has taken through history. Any response that can be taken to mitigate these risks is itself limited by this very form of production that has been performed all these many years.

Food production also links directly to natural resource issues. There is research showing that when evaluating the overall value chain of food, food supply to Japan consumes the equivalent of one-quarter of Japan’s final energy consumption. Other issues concern the use of synthetic fertilizers which consume energy and the depletion of phosphorous and potassium resources which are used in agrochemicals. The constraint of resources has the potential to further heighten in future the risks of food production and to deepen restraints on potential supply capacity. It can be possible through international treaty to increase food production and distribution in regions that have a high level of resource efficiency in order to decrease the amount of energy required for food supply overall, as a way to deal with the constraint of resources. According to my calculations, changing the pattern of the world’s food supply would save at most about 20% in the total amount of energy used at the time of supply in production, processing and transport. This results from optimizing the areas that supply produce that can be stored and shipped over long distances such as feed, fat and oil products, and tubers.

At this juncture however, nations tend to aspire to some degree to self-sufficiency from the point of view of maintaining safety, even if production remains with low economic and low energy efficiency, so it would be difficult to maximize efficiency in resource use. A necessary condition for globally cooperative action would be confidence building between producer nations and consumer nations. While memory is still fresh of the insurrection seen in producer nations during the food price jumps of 2008 that claimed precedence for the domestic consumer, as well as the restrictions placed on exports by those nations, it is difficult to imagine that consumer nations would care to adopt an option that would further increase their dependence on imports. At this time, MAFF has settled on a Basic Plan for Food, Agriculture and Rural Areas as of March 2010, which sets a goal of raising self-sufficiency to 50% by the year 2020 (currently 40 %). This plan seems based on the implicit assumption that in order to stabilize supply, domestic production is important. So the burden on the people of Japan will at least temporarily and inevitably increase.

Benefits of Plant Factories

Although plant factories have the difficulty of high initial investment and high operating costs, they comprise a new paradigm for agriculture which through the synergy of diverse technologies will reduce the volatility that accompanies food production, besides boosting productivity. Future development of the plant factory concept may become more wholehearted as it is seen to help alleviate the structural food supply problems stated above. We can expect that many benefits of the plant factory production system would link directly to the improvement of food problem challenges.

First off, via the introduction of controlled environment food production, we can anticipate the reduction of production risk which is one of the biggest problems faced by agriculture. Because controlled environment food production does not have fluctuating yield due to weather impact, in contrast to open field production, the higher the share of plant factory product on the market the better that fluctuation in agricultural product prices can be kept down. Additionally, exploiting the unique feature of plant factories which is to produce the final product in a shorter period of time, by increasing the operating rate when bad weather is predicted even with a short lead time, supply and demand can be maintained at a reasonable level even in times of crop failure. In particular, over production of supply by a certain percentage by plant factories would make it possible to ship vegetable produce, which is difficult to store for long periods of time, to the open market in the event of decreased supply due to the impact of weather such as we have seen this past spring. In this area, the special characteristics of plant factories namely “shorter growing period,” “smaller ratio of variable costs spent on supplemental production,” and “longer storage time for produce,” manifest their competitive edge. Considering that today in relatively large scale plant factories the operating rate is still low at about 30%-50%, we can see that there is plenty of potential for supplemental production. Overseas as well, the significance of the fact that even in times of drought a stable supply can be guaranteed will certainly become more meaningful, given time.

Not only in Japan but also overseas there is great potential in particular for controlled environment food production systems that use renewable sources of energy. An example is the Middle East where due to increased demand and shortage of arable land there is instability in food supply. The region however is blessed with rich fossil fuel reserves and solar energy. In the Middle Eastern desert using natural sunlight to grow plants and solar energy to power air conditioning and nutrient management among other systems, even assuming that water for evaporative cooling and watering plants would be obtained through desalination, the cost of one kilogram of high yield performance rice (four crops per year) can be calculated at about 300-400 yen. This is still fairly expensive compared to the local cost of imports, but when considering the risks of unexpected changes in the environment and changes in local policy regarding the acquisition of foreign land for the purpose of cultivating food, the additional cost could be seen as the cost of ensuring safety.

Abu Dhabi and other Middle Eastern nations are planning for their post-fossil fuel economies as well as their own domestic energy supply to be made up by sunlight and solar energy. For social systems that have adopted this type of new energy infrastructure, the significance of bringing in food supply systems based on plant factories is major. Not only do the sites closely resemble solar energy plants, but there is also latent demand nearby in many cases. In particular, in these nations the demand for food will increase together with the population in future, while on the other hand the population increase in major importers, like India and Pakistan (more than 1% annual growth), of such products as rice will make the supply become even more difficult than now. Regarding available land for the location of plant factories, land that is not being repurposed and/or desert land can be used and which represent only a small percentage of the whole, so it is assumed that the difference in cost between plant factory product and imported product, especially considering global food supply and demand as well as sharp potential jumps in resource prices, will most likely shrink. In addition, by imbuing users with the strengths and added value of plant factory product which are comprised by safety, longer period of freshness, higher yield and no need to wash produce, I believe that plant factory produce will only become more competitive.

Further, besides the availability of land and the economic efficiency but also the extremely high constraints on the use of water serve to be excellent conditions in considering the advance of plant factories into the aforementioned regions. Agricultural production till now has continued to rely on underground water, but opinion is strong that these resources should be given first to drinking water, and the government is placing restrictions on the category of produce to be cultivated and on land use. This is why governments are trying to stabilize supply by importing agricultural product produced in farmland acquired in neighboring regions, but considering the heightened worries internationally about the acquisition of farmland by foreign countries, the current policy seems not to be sustainable. In this way, the significance of completely closed systems that circulate water to create a virtually 100% renewable resource is great.

Towards the Active Use of Plant Factories

In order to make much greater use of the potential of plant factories, I would like to make the following three propositions.

<Proposition 1: Promote Overseas Development of Plant Factories>

Tight supply/demand conditions in certain regions overseas as mentioned above are remarkably likely to manifest in areas with growing population and shortage of arable land, so the efficiency of exporting plant factories system is high. In particular if solar fuel cells or other means are obtained independently to secure the energy supply for the factory, the feasibility of the land use will become much higher. For plant factories, it is not enough to just build production facilities in the locality – suitable cultivation technology and environmental control technologies are also needed. In order to ensure the success of the export of these facilities an exchange of human talent is a prerequisite. This will also enable relationship building on the medium to long term basis between Japan and its counterparts overseas.

Whereas currently efforts are continuing in a groping fashion on the optimization of an integral combination of these technologies, it is probably necessary to speed up this process. Also as a part of marketing, it would be in our interest to develop the type of demonstration plant factory facilities, which are growing slowly in the shopping streets of many localities within Japan today, at for example the Japanese embassies in foreign countries. It is certain that this is a great opportunity to exploit Japanese technological strengths such as renewable energy technology for power supply, technology for energy saving light, heat and ventilation control within the facility, and robotic technology for monitoring and harvesting of crops.

<Proposition 2: Deregulate on a Par with Existing Agricultural Deregulation>

Within Japan, there are many cases where land used for plant factories is not officially recognized as being farmland, and so is excluded from benefits that are ordinarily applied to farmland such as tax deferment or exemption, reduced estimated taxes or preferential tax rate. Further, attempts to newly enter the industry are fraught with additional indirect costs such as overly equipped or redundant facilities being required by various organizations in connection with the site location or construction. The current state of affairs also forces constraints on site location due to the City Planning Law. To make conditions on a par with other agricultural producers, we should review programs such as applying farmland level taxation to plant factory facilities, namely land where food production takes place in a factory.

<Proposition 3: Make It Possible to Use Renewable Energy Systems>

Finally, regarding the increase in energy consumption which is a challenge in the introductory period, and in order to reduce the impact of resource price fluctuation so as to reduce energy expenditure, we must consider promoting the introduction of systems that would combine renewable energy sources with energy saving equipment. At present renewable energy is high cost, but if development advances and new technology diffuses, we can expect costs to go down. For example, one plan is to temporarily introduce the surplus electricity buyback program, which has been brought in for residential locations, to plant factories in order to promote more widespread use. If facility costs continue to decline through programs like this, this will have a beneficial effect on plant factory operation and more factories will open. What has been feared with total fixed price buyback systems as in the examples of Germany and Spain is that there is no way to predict the amount to be brought in, and as a result no way to estimate the burden to be borne by the people. Since the merits of the system can be enjoyed simply through the introduction of power generating facilities, it can happen that a rush to introduce the system occurs, but the previously noted problem can be avoided by government support of the system based on the condition that it is done in conjunction with the introduction of a plant factory system. If the real aim is to make effective use of limited national land or to encourage the spread of solar generated electricity, then there is not much basis for giving favorable treatment to installation of solar panels just on the roofs of household residences. First off, we must advance an expanded concept of the target for installation to include industrial facilities such as plant factories, which will have a greater social impact. If as a result this leads to an opportunity for greater diffusion of both these industries which do have a major impact on the social fabric, then the collateral effect of the support policies will be wider, and we can assume that the rate of dependence of both industries on preferential government treatment will ultimately decline. In factory production itself, in order to expand produce categories beyond vegetables and fruits, it will be necessary to use more energy, and we will need to make more effort to cut costs. We must avoid becoming trapped in even more unfavorable conditions due to high jumps in fuel costs while we advance under conditions that are already unfavorable for economic efficiency.

As the global situation in energy and food is expected to continue to change, the diffusion of plant factories will reduce the volatility associated with agriculture, and may be strongly anticipated to lead to enhancement of Japan’s ability to compete in the global marketplace as a new industry that unites some complex technologies.

One thought on “Turning Agriculture into Industry— Rising Above Environmental Dependence”